Suzhou City Sawers Hydraulic Lifting Machinery Co., Ltd.

0512-66800819

0512-66800289

Loading and unloading platform series

Shear fork hydraulic lifting platform series

SJG scissors lift elevator

Guide rail hydraulic lifting platform

High-altitude operating platform series

Aluminum alloy high-altitude operating platform

Hydraulic cart series

Custom-made special hydraulic lifting platform

Contact us

Manager Li's phone/WeChat | 15962195095

Manager Li's phone/WeChat | 15962195095

Miss Shen's phone/WeChat | 1585147743

Miss Shen's phone/WeChat | 1585147743

Miss Yi's phone/WeChat | 13913146909

Miss Yi's phone/WeChat | 13913146909

Miss Zhuang's phone/WeChat | 15705165169

Miss Zhuang's phone/WeChat | 15705165169

Phone: 0512-66800819/66800289

Phone: 0512-66800819/66800289

Transmission: 0512-66800020

Transmission: 0512-66800020

Email: suzhousuowosi@163.com

Email: suzhousuowosi@163.com

Address: Suzhou High tech Industrial Development Zone Science and Technology

No. 38 Lijiang Road (South of Putuo Mountain Road)

Address: Suzhou High tech Industrial Development Zone Science and Technology

No. 38 Lijiang Road (South of Putuo Mountain Road)

- Description

- Advantages

- Parameters

- Image

- More product

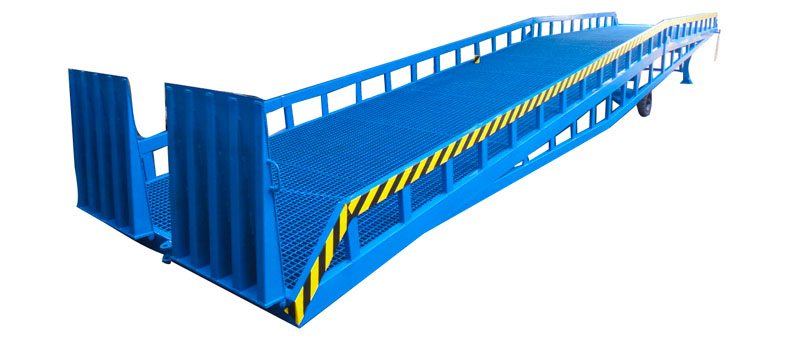

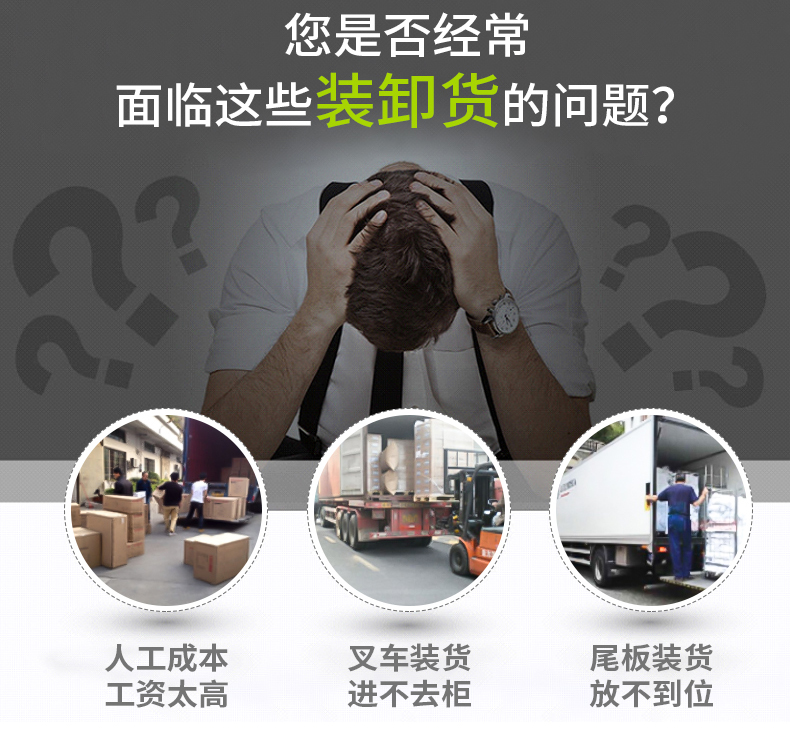

The mobile hydraulic loading bridge is a specialized auxiliary equipment used in conjunction with forklifts for loading and unloading goods. With it, forklifts can directly enter the car compartment from the ground for loading and unloading operations.It can improve the loading and unloading speed of goods, save time and manpower in loading and unloading work, and is your effective assistant in loading and unloading goods. Only one person is required to operate without the need for power supply, which can achieve safe and fast loading and unloading of goods. The mobile boarding bridge is used for cargo platforms and mobile loading and unloading sites without loading and unloading equipment, and is a cargo loading and unloading auxiliary equipment used in conjunction with forklifts. The height can be adjusted according to the height of the car compartment, and forklifts can directly enter the interior of the compartment through this equipment for bulk loading and unloading of goods.

When using a hand pump on a mobile boarding bridge, first lower the return valve knob and tighten it clockwise. Press the handle to slowly raise the boarding bridge. When lowering, release the return valve knob (rotate counterclockwise) to lower the axle by its own weight. When in use, the manual valve should be released to keep the hydraulic piston rod in a stress free state. Press the lifting handle to raise the boarding bridge above the bottom of the carriage. Open the return oil valve, lower the mobile boarding bridge and smoothly overlap the lip plate to the rear of the vehicle. Use a chain to firmly secure the mobile boarding bridge and the vehicle. At this time, the hydraulic system is not under force and can start working. After the homework is completed, release the fixed chain, press the handle to lift the boarding bridge, drive the vehicle away, and reset the boarding bridge. Lift the rear of the boarding bridge and move it onto the vehicle. When using the boarding bridge, keep the hydraulic lifting platform table stable and firm, and the fixed chain must be firmly fixed to the vehicle. During the descent process of the mobile boarding bridge, it is strictly prohibited for all personnel to climb, and overloading operations are strictly prohibited during the use of the boarding bridge. The hydraulic oil used should be kept clean and free from water and other impurities. It is generally replaced every six months. When the boarding bridge malfunctions, the operation should be stopped immediately to eliminate the problem. The utility model relates to a mobile boarding bridge. The boarding bridge includes a bridge body, railings on both sides above the bridge body, and a landing plate at the front and rear ends of the bridge body. It also includes a hanging chain, a traction rod, a hand pump device, wheels, wheel frames, and oil cylinders; The hanging chain is located on both sides of the front end of the bridge body, the traction rod is located below the bridge body, the hand pump device is located on one side below the middle of the bridge body, and the wheels are installed on the bottom surface of the middle of the bridge body. The front end is equipped with two wheels, and the rear end is hinged with the bottom surface of the middle of the bridge body. The utility model has the advantages of small footprint, wide range of use, and simple operation.

Product brand: Susovos ®

Product size: see reference parameters for details (supports non-standard customization)

Product color: customized according to customer needs

Product use: Used in conjunction with forklifts and transport trucks to quickly load and unload goods in bulk from containers or trucks

Applicable places: various factories, warehouses, yards, stations, docks, grain depots, etc

Product transportation: door-to-door delivery nationwide

Product Description:

The mobile hydraulic loading bridge is a specialized auxiliary equipment used in conjunction with forklifts for loading and unloading goods. With it, forklifts can directly enter the car compartment from the ground for loading and unloading operations. It can improve the loading and unloading speed of goods, save time and manpower in loading and unloading work, and is your effective assistant in loading and unloading goods.

Only one person is required to operate without the need for power supply, which can achieve safe and fast loading and unloading of goods. The mobile boarding bridge is used for cargo platforms and mobile loading and unloading sites without loading and unloading equipment, and is a cargo loading and unloading auxiliary equipment used in conjunction with forklifts. The height can be adjusted according to the height of the car compartment, and forklifts can directly enter the interior of the compartment through this equipment for bulk loading and unloading of goods.

All rust removal has undergone sandblasting and shot blasting treatment, which is now a thorough and efficient rust removal method. It is faster and cleaner than manual polishing, and the surface is smooth, increasing the adhesion between the paint and extending the durability of the paint.

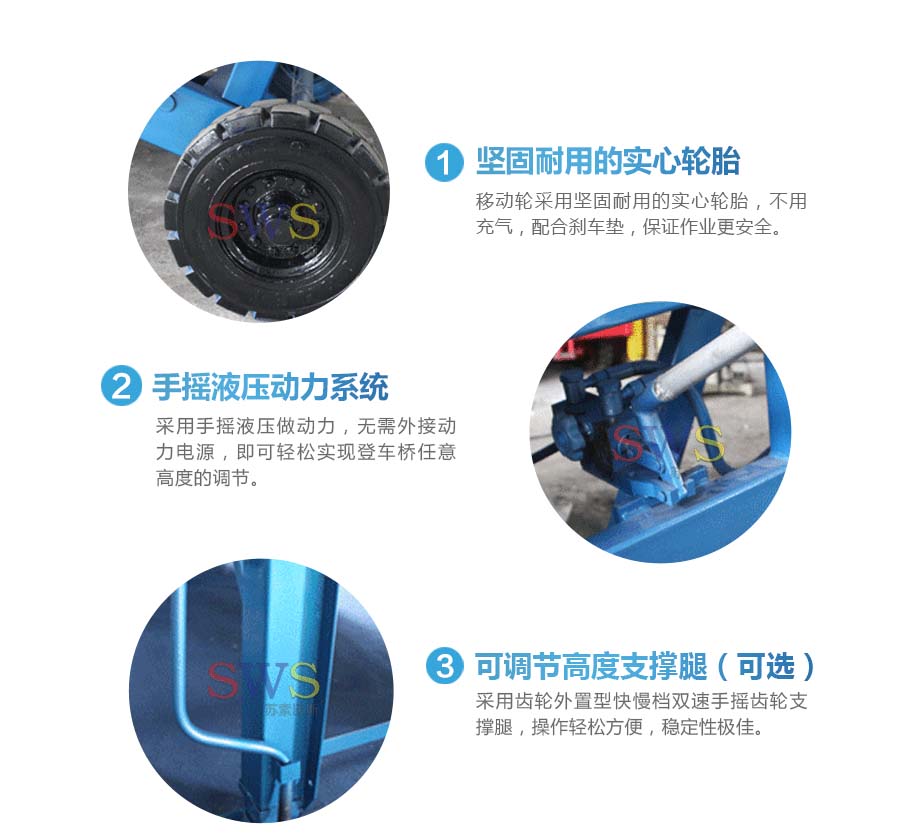

By using artificial hydraulic power, the height adjustment of the boarding bridge can be easily achieved without the need for external power supply.

The adjustable length of the cable chain is used to hook the vehicle, ensuring that the boarding bridge always fits tightly with the vehicle even in case of displacement.

The mobile wheel is made of solid tires, which do not require inflation. It is sturdy and durable, combined with brake pads to ensure safe operation.

The rear folding transition plate and forklift traction hook can easily move the boarding bridge.

A layer of toothed anti-skid plates or checkered plates is laid on top of the bridge body. The mesh is twisted and hollow, which not only improves the reliability of work, but also prevents the accumulation of grease, dirt, rainwater, and ice and snow.

This equipment is particularly suitable for explosion-proof and flammable places, with manual hydraulic power, without generating sparks and no worries.

The power can be configured as: manual hand pump power. Electric power.

Ensure that the seal is NOK from Japan.

Ensure that the oil cylinder is processed by iron cutting and rolling.

产品型号:

型号 载荷 平台尺寸mm 工作高度mm T A B C D E F G H I J DCQY6-0.8 6 7000 2200 1000 300 10500 2000 2080 1000 800 1800 DCQY8-0.8 8 7000 2200 1000 300 10500 2000 2080 1000 800 1800 DCQY10-0.8 10 7500 2400 1000 300 11200 2000 2100 1000 800 1800 DCQY15-0.8 15 9000 4000 1000 300 14300 2100 2200 1000 800 1800 DCQY20-0.8 20 10000 4000 1000 300 15300 2700 2800 1000 800 1800 型号 载荷 平台尺寸mm 工作高度mm T A B C D E F G H I J DCQY6-0.6 6 7000 2200 1000 300 10500 2000 2080 1200 600 1800 DCQY8-0.6 8 7000 2200 1000 300 10500 2000 2080 1200 600 1800 DCQY10-0.6 10 7500 2400 1000 300 11200 2000 2100 1200 600 1800 DCQY15-0.6 15 9000 4000 1000 300 14300 2100 2200 1200 600 1800 DCQY20-0.6 20 10000 4000 1000 300 15300 2700 2800 1200 600 1800