Suzhou City Sawers Hydraulic Lifting Machinery Co., Ltd.

0512-66800819

0512-66800289

Loading and unloading platform series

Shear fork hydraulic lifting platform series

SJG scissors lift elevator

Guide rail hydraulic lifting platform

High-altitude operating platform series

Aluminum alloy high-altitude operating platform

Hydraulic cart series

Custom-made special hydraulic lifting platform

Contact us

Manager Li's phone/WeChat | 15962195095

Manager Li's phone/WeChat | 15962195095

Miss Shen's phone/WeChat | 1585147743

Miss Shen's phone/WeChat | 1585147743

Miss Yi's phone/WeChat | 13913146909

Miss Yi's phone/WeChat | 13913146909

Miss Zhuang's phone/WeChat | 15705165169

Miss Zhuang's phone/WeChat | 15705165169

Phone: 0512-66800819/66800289

Phone: 0512-66800819/66800289

Transmission: 0512-66800020

Transmission: 0512-66800020

Email: suzhousuowosi@163.com

Email: suzhousuowosi@163.com

Address: Suzhou High tech Industrial Development Zone Science and Technology

No. 38 Lijiang Road (South of Putuo Mountain Road)

Address: Suzhou High tech Industrial Development Zone Science and Technology

No. 38 Lijiang Road (South of Putuo Mountain Road)

- Description

- Advantages

- Parameters

- Image

- More product

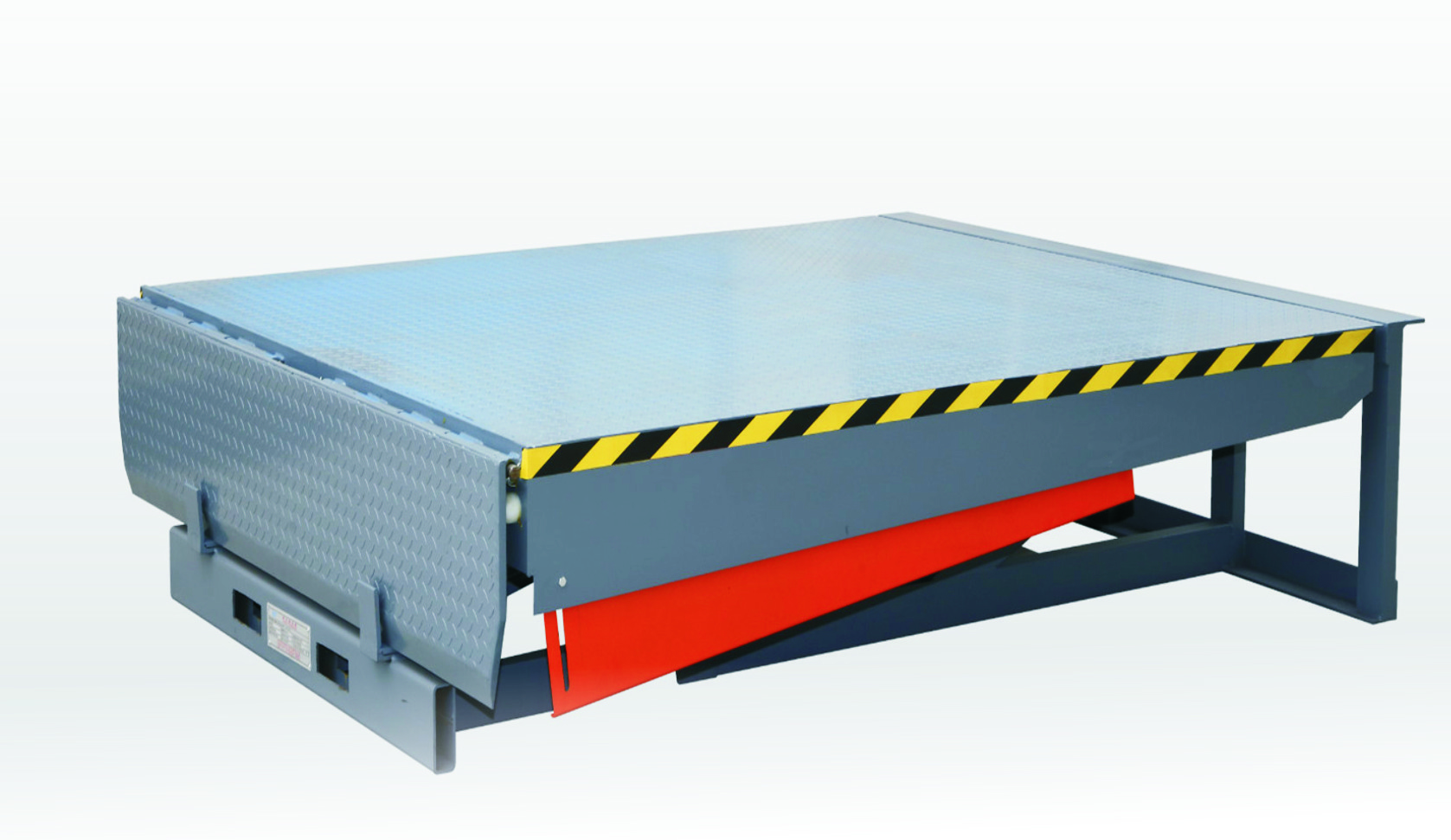

Fixed hydraulic boarding bridge (also known as height adjustment plate/unloading platform or electric hydraulic platform) is a specialized auxiliary equipment for fast loading and unloading of goods. It is installed on the platform or building, overlapped on the freight car, and adjusts the height difference between the platform, building floor, and the car. The flippable overlap plate at the front end of the boarding bridge always adheres tightly to the carriage during loading and unloading of goods. The angle adjustment function of the boarding bridge enables a bridge to be built between the truck and the building floor, allowing various transport vehicles to smoothly pass through the boarding bridge and transport goods between the building floor and the carriages. Moreover, with only one operator working, fast loading and unloading of goods can be achieved. It enables enterprises to reduce a large amount of labor, improve work efficiency, and obtain greater economic benefits. It is the optimal choice for modern enterprise safety production and improving material circulation speed.

Greater economic benefits.

Fully hydraulic drive, easy to operate and reliable to operate.

The lip plate is connected to the platform using a full length shaft, which has high strength and good reliability.

◇ Imported seals are used to ensure excellent sealing performance of the hydraulic system.

Adopting imported integrated modular hydraulic station, with good sealing performance and long service life.

◇ High strength; U” The design of the shaped beam can ensure its high load and long-term operation without deformation.

The countertop is made of anti slip patterned steel plate, which has good anti slip performance.

Install anti rolling foot skirts on both sides to prevent accidental injuries caused by toes extending into the platform.

◇ Equipped with safety support rods to ensure maintenance personnel enter the interior of the boarding bridge for maintenance

Standard configuration:

a. Original imported hydraulic system b, safety maintenance support rod c, anti pressure toe guard board

d. Anti collision rubber cushion

Optional configuration:

a. AC220V/50HZ b, hydraulic system with stop device

Product advantages:

1、 All rust removal has undergone sandblasting and shot blasting treatment, which is now a thorough and efficient rust removal method. It is faster and cleaner than manual polishing, and the surface is smooth, increasing the adhesion between the paint and extending the durability of the paint.

1、 Fully hydraulic drive, easy to operate and reliable to operate.

2、 The lip plate is connected to the platform using a full length shaft, which has high strength and good reliability.

3、 The use of imported seals ensures excellent sealing performance of the hydraulic system.

4、 Adopting imported integrated modular hydraulic station, with good sealing performance and long service life.

5、 Adopting anti slip patterned steel plates, the platform has good anti slip performance.

6、 The design of high-strength manganese steel rectangular pipes can ensure that they do not deform during long-term operation under high loads.

7、 Ensure that the seal is NOK from Japan.

8、 Ensure that the oil cylinder is processed by iron cutting and rolling.

型号 载荷 (kg) 平台尺寸

(mm)L*W唇宽度

(mm)L1*W1行程(mm) 功率(kw) 地坑尺寸 (mm) 整机重量

KG电源电源

V/HZL W H DCQ6-0.5 6000 2000*2000 400 ±250 0.75 2000 2040 600 810 AC380/50HZ DCQ6-0.6 6000 2500*2000 400 ±300 0.75 2500 2040 600 930 AC380/51HZ DCQ8-0.5 8000 2000*2000 400 ±250 0.75 2000 2040 600 860 AC380/52HZ DCQ8-0.6 8000 2500*2000 400 ±300 0.75 2500 2040 600 980 AC380/53HZ DCQ10-0.5 10000 2000*2000 400 ±250 1.1 2000 2040 600 1050 AC380/54HZ DCQ10-0.6 10000 2500*2000 400 ±300 1.1 2500 2040 600 1180 AC380/55HZ